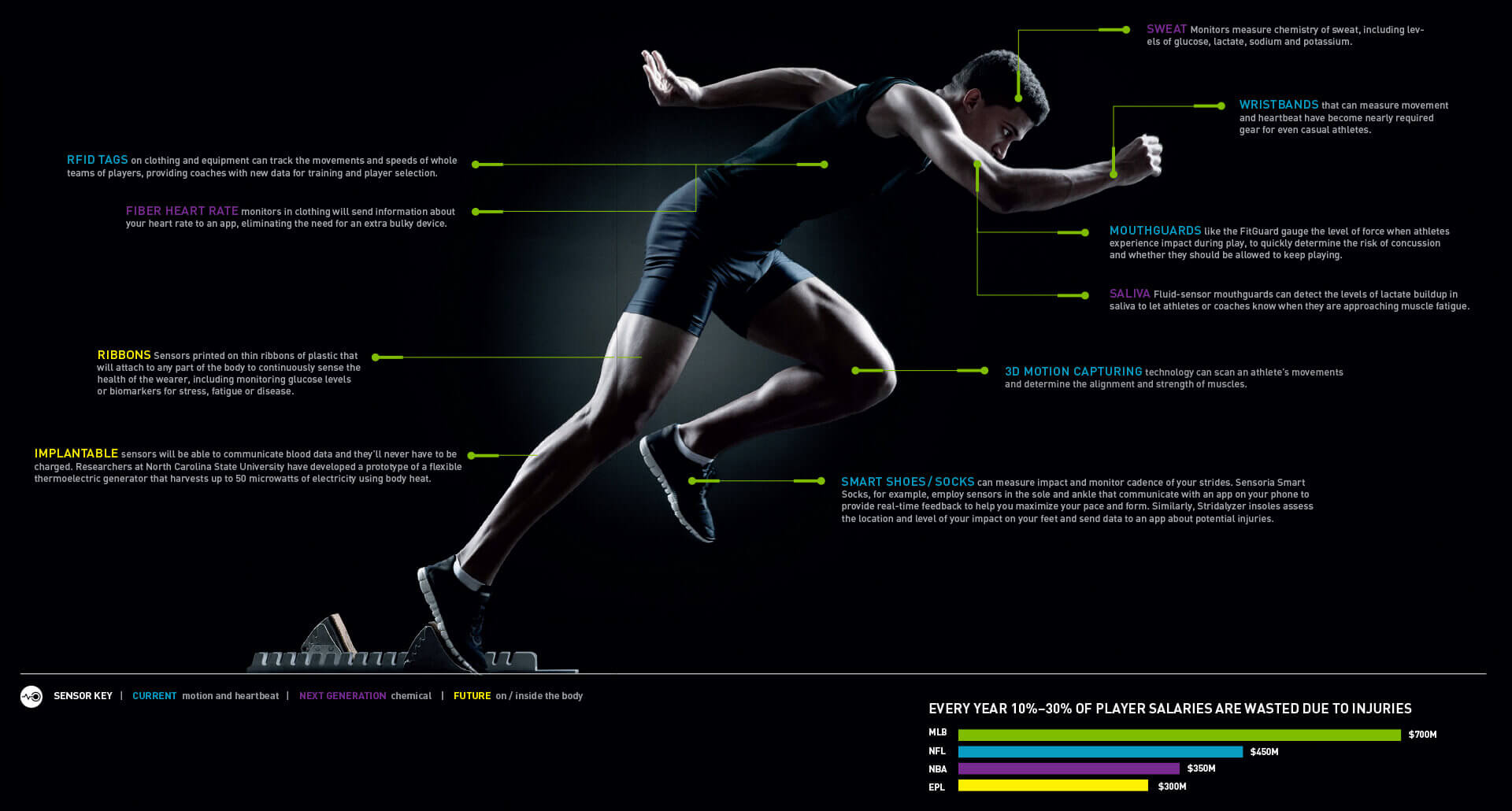

Historically, sensor data has been used to monitor workload during training weeks to pinpoint fitness levels. Players first wore vests, then chest straps. In two quick years, the technology has shrunk from wristbands to waist clips to sensors no bigger than a band-aid. Now a sensor can be attached as a temporary tattoo, and soon they will be commonly implanted under the skin.

But more important than the sensor size is the increasingly accurate and complex data that is being harvested. Finding once-hidden biometric patterns in individual athletes has become possible. Some players get injured when they train too hard. They have a steady slope pattern. Other players push through an upper limit, and only by training very intensely do they reach a zone where they don’t break down. They have a roller-coaster pattern. Every athlete has her own equivalent of a pitch count. With new technology, coaches can learn how hard to train an individual athlete—without overtraining.

Even “freak” injuries are avoidable. A majority of contact injuries have been considered random. Who could predict an opponent would fall in front of your player and cause him to hyperextend a knee? It turns out that fatigue significantly affects reaction time, reducing peripheral vision and increasing the odds of injury. Tired athletes incur a much higher rate of contact injuries than fit, well-rested athletes, who spot impending contact and make adjustments to avoid it.

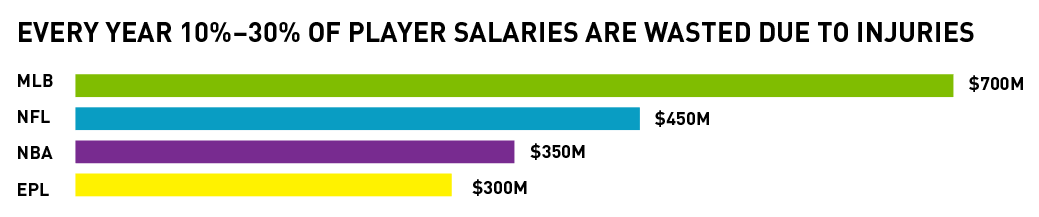

The connection between lost dollars and lost games is quantifiable. For every $2.3 million in salary cap dedicated to players on the disabled list, the average NFL team will lose one additional game. Salary wasted on injured players accounts for as much as 89% of the variance in NFL teams’ win-loss records.

Machine learning software systems have been turned loose on the avalanche of athlete performance data coming from new sensors that are wearable, implantable or ingestible. Not only will overuse injuries be avoided—so will contact injuries that were previously considered random accidents.

A Tale of Two Seasons

Five professional teams used Kitman Labs’ machine-learning injury-prediction system during their 2015 seasons to identify warning signs of potential injuries.

So much data is being collected, in so many novel ways, that we can be distracted from the real question: what are we going to do with it?

In-game performance decisions. The data can tell you the starter runs 20 mph in practice, while the second-stringer runs 19 mph. On game day, sensors will alert the coaches that the starter has dropped to 17 mph with fatigue, and it’s time to sub in the bench player.

Pubertal status calibration in youth sports. Forever, youth sports talent identification has famously favored older athletes within a given age bracket who are more mature. But late-blooming 15-year-olds can’t really be fairly compared to 13-year-olds, either. Sensors and machine learning will finally solve this conundrum, factoring skeletal age and hormone escalation into player experience and performance metrics to make sure the players with the most potential are picked over the players who merely hit puberty early.

Career extension. We don’t really know whether aging athletes, in order to compete, need to put in double the training load or if they need to emphasize getting rest between workouts. The science of career extension is not really a science yet—mainly hunches and anecdotes. “Recovery” will become an accurately measurable event, parsed through tangible factors. Expect to be surprised; much of the “wisdom” we take for granted will be overturned.

What Every Coach Knows

-

Muscles produce lactic acid as a by-product when the body shifts from aerobic to anaerobic exercise.

-

Lactic acid causes soreness and needs to be cleared in order to perform again.

-

High-performance athletes produce less; it’s a waste product and not used for fuel by the body.

What Science Has Found

-

As muscles fatigue, they depolarize like worn-down batteries, losing power. Lactate counteracts this depolarization.

-

Soreness is muscle fiber damage and inflammation. Lactate triggers cells to produce more mitochondria, the factories of energy.

-

High-performance athletes burn it up better; 75% of lactate is used as fuel for muscle contractions.

Controversies between players, teams and leagues over data privacy are inevitable.

Players want to keep their biometric data private. Teams will want to share the biometrics to engineer trades. Leagues will want to sell the data as streams, either to apps that visualize the data to enhance storytelling or to fantasy players who want a leg up on their competition. (“Don’t play Johnson today—his hematocrit ratio is low.”)

Expect class-action lawsuits, likely from players or from media. Much like MLB’s legal battles a decade ago with fantasy sites over statistical data, courts will be asked to rule on whether specialized data is “historical news,” and therefore can’t be owned. Courts will also decide whether players have rights to the data measuring their performance, even if it’s collected and held by the teams. Likely, biometric/health data will be viewed differently by the courts than performance data.

Contracts today include performance bonuses and body-weight clauses. The contracts of the future will contain speed and strength standards to maintain—and biometric marker levels to meet. Just as today’s players hire private trainers, professional athletes of the future will hire their own experts not only to acquire health and performance data, but also to analyze those metrics.

Everyone involved will worry whether the data has been tampered with. How do we know a statistician hasn’t altered the numbers to make a player more attractive?

The answer lies in blockchain technology like Tierion, which can:

- Guarantee that data is timestamped and unaltered.

- Require passcodes to view the data.

- Track data wherever it goes on the internet, making sure the rights holders are paid.

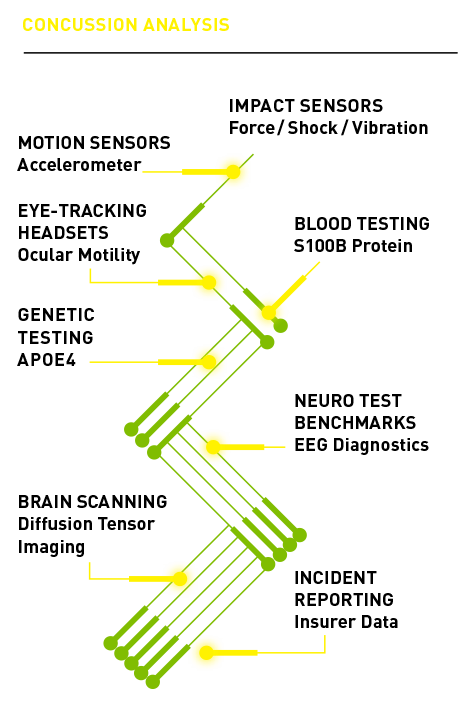

Boxing at the Rio Olympics eliminated headgear, due to a counterintuitive finding from the International Boxing Association: headgear was correlated with more concussions, not fewer. Not only does the soft padding not stop blunt force hits, but the bigger target leads to more head whips from blows. Concussion research is about to take huge strides as data is aggregated from an array of new sources. Motion and impact sensors on helmets, mouthguards and headbands are just part of it. Eye-tracking headsets have jumped from the labs to the sidelines to test athletes’ brain function immediately after any blow. Blood tests can now spot concussive trauma through elevated levels of the S100B protein. Every high school is requiring preseason benchmark neurological tests; insurers of youth leagues are now mandating head trauma incident reporting. All this data will be crossed with genetic testing for the APOE4 variant, which has been linked to concussions, and artificial intelligence will discover patterns heretofore unseen. Should helmets be hard and super-slippery to deflect impact? Or should they crush like car bumpers to absorb impact? We’re about to find out.

Many of these technologies, such as wearables and video, are still new and the data can be inaccurate. We have seen wearables giving wrong data as often as 30% of the time. Numbers also tend to be calibrated for male rather than female athletes. If we’re making health and safety decisions with the wrong data, we’re putting our athletes at greater risk and diminishing trust in the technology hype. Improving data accuracy is critical as the industry moves forward.

Jane Gideon

CEO, WellPlayed Sports

The players don’t get the data, it’s fed to the coaches right after practice. And in the locker room, there is definitely fear among the players about all the data being collected. We’re afraid we’re going to get cut, because the data will be able to spot a decline in our performance that can’t be spotted with the naked eye.

Doug Baldwin

Seattle Seahawks wide receiver

We aren’t quite to the stage where we can scan you with a tricorder like the ones they use on ‘Star Trek’ and diagnose your medical condition, but we’re getting there.

James Watkins

Professor of polymer science and director of the Center for Hierarchical Manufacturing